DIN SPEC “Quality requirements for composite processes”

"Fast-Track" to Standard: Consortium Initiates DIN SPEC 35255 "Quality Requirements for Composite Processes". Now available free of charge in German and English: https://www.beuth.de/de/technische-regel/din-spec-35255/373719663

Standards and specifications are powerful instruments for quality assurance and are of particular importance for technology transfer. Experiences from, for example, welding and adhesive bonding technology impressively demonstrate that thanks to uniform standards and practical quality management systems, trust and market acceptance of a wide variety of technologies can be significantly increased.

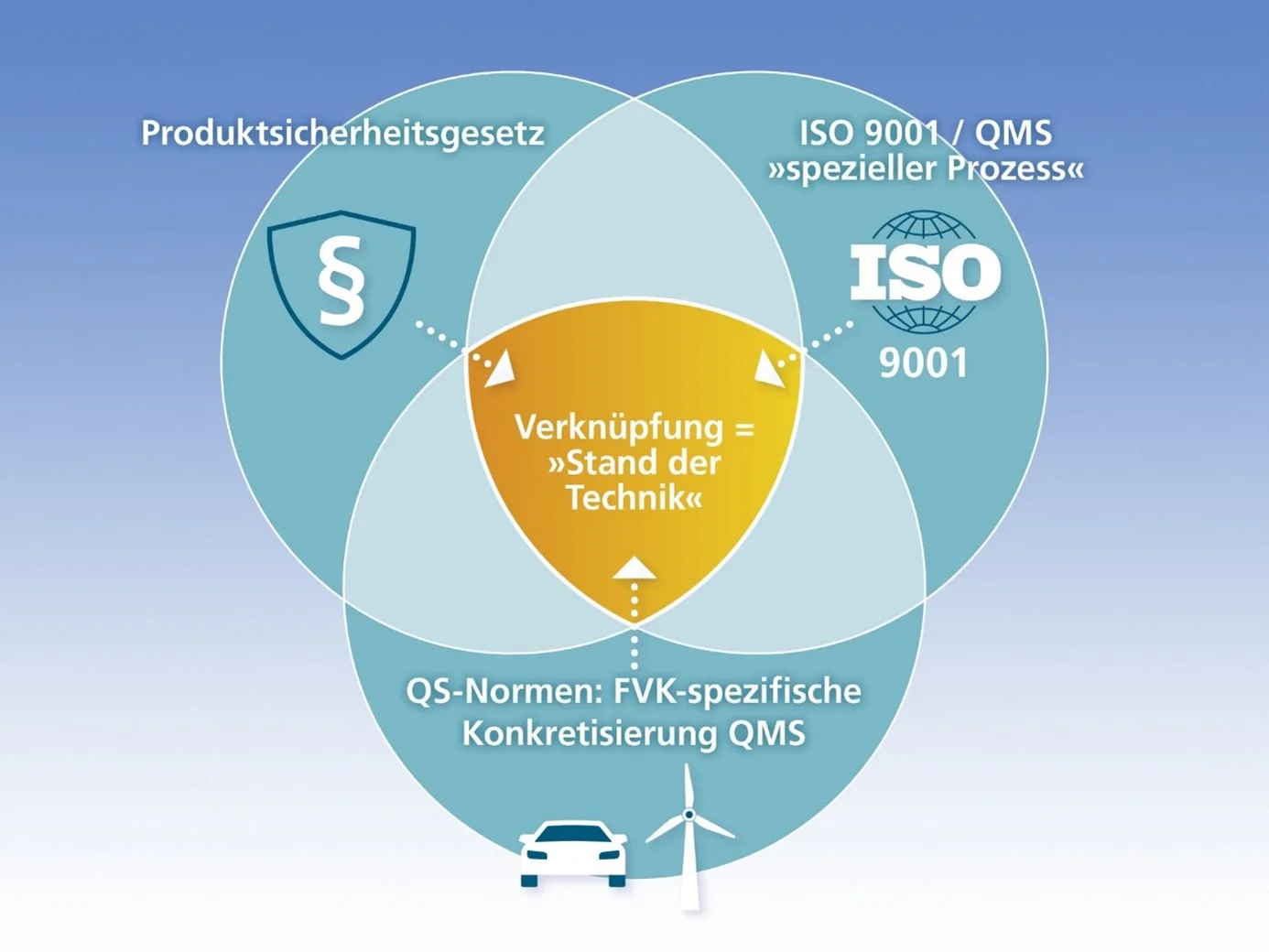

Quality standards are also crucial for fiber-reinforced plastic processes. Fiber-reinforced plastics, or composites, are widely used due to their lightweight potential, particularly in the fields of automotive, rail vehicles, shipbuilding, aerospace, and wind energy. The manufacturing process is demanding. A standardized process for quality assurance in the production and maintenance of composite components is therefore essential.

The first step toward improving composite quality was initiated by @Fraunhofer IFAM through the formation of a consortium that was registered with and supported by DIN. The joint alliance, consisting of industry partners, certification bodies, and research institutions, set itself the goal of developing a set of rules for "Quality Requirements for Fiber-Reinforced Plastic Processes" along the entire composites process chain.

With the new DIN SPEC 35255, the consortium has now achieved a breakthrough. The new DIN SPEC defines standardized quality requirements for fiber-reinforced plastic processes. Analogous to the established welding and bonding standards, DIN SPEC 35255 also contains the three core elements: the classification of composite components according to safety requirements, the requirements for personnel competence, and the verification of actual stress compared to maximum load capacity.