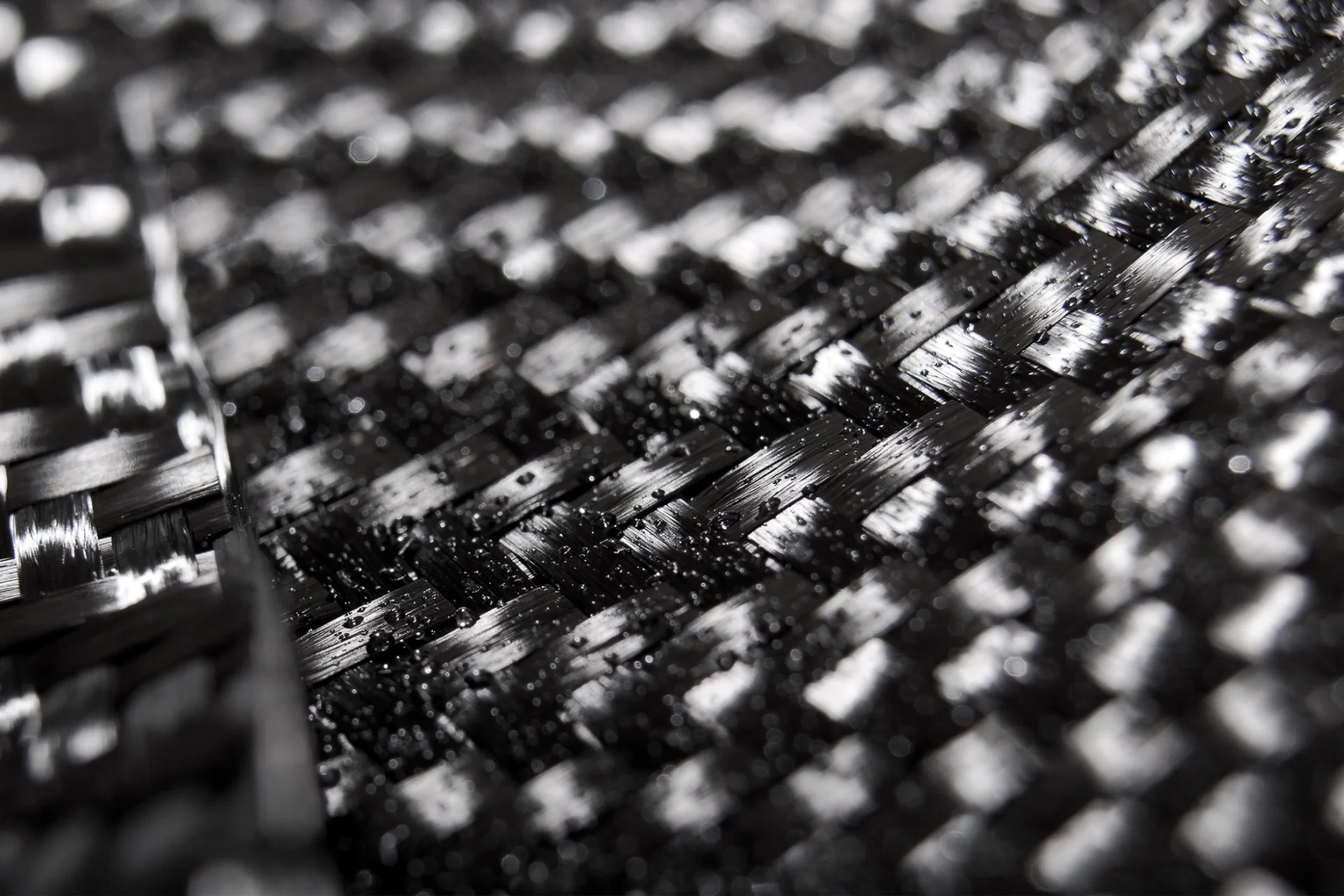

Where others still rely on steel, we go one step further: composite materials. They are lighter, more durable, and more sustainable—a real technological leap forward for maritime and military applications.

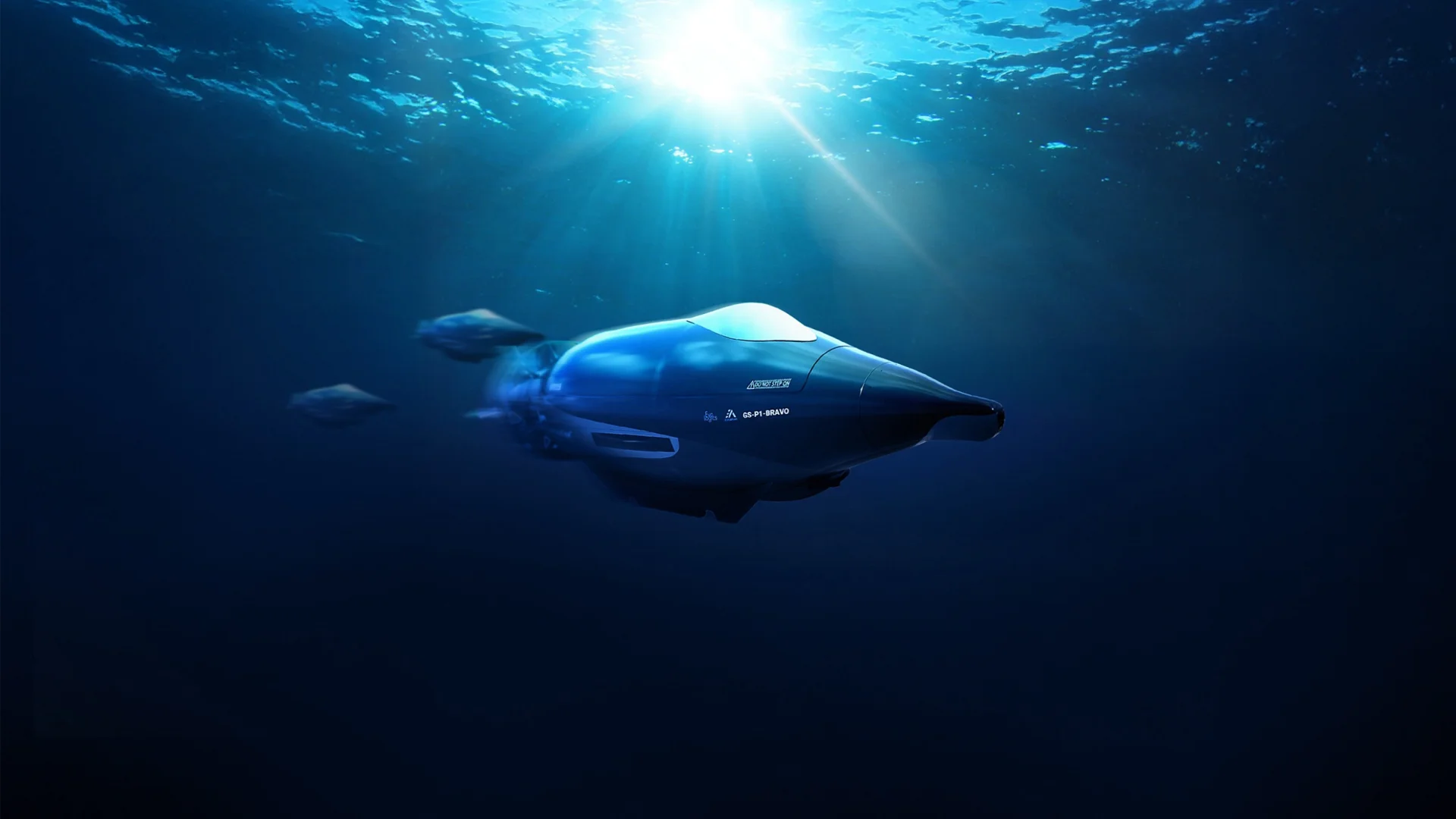

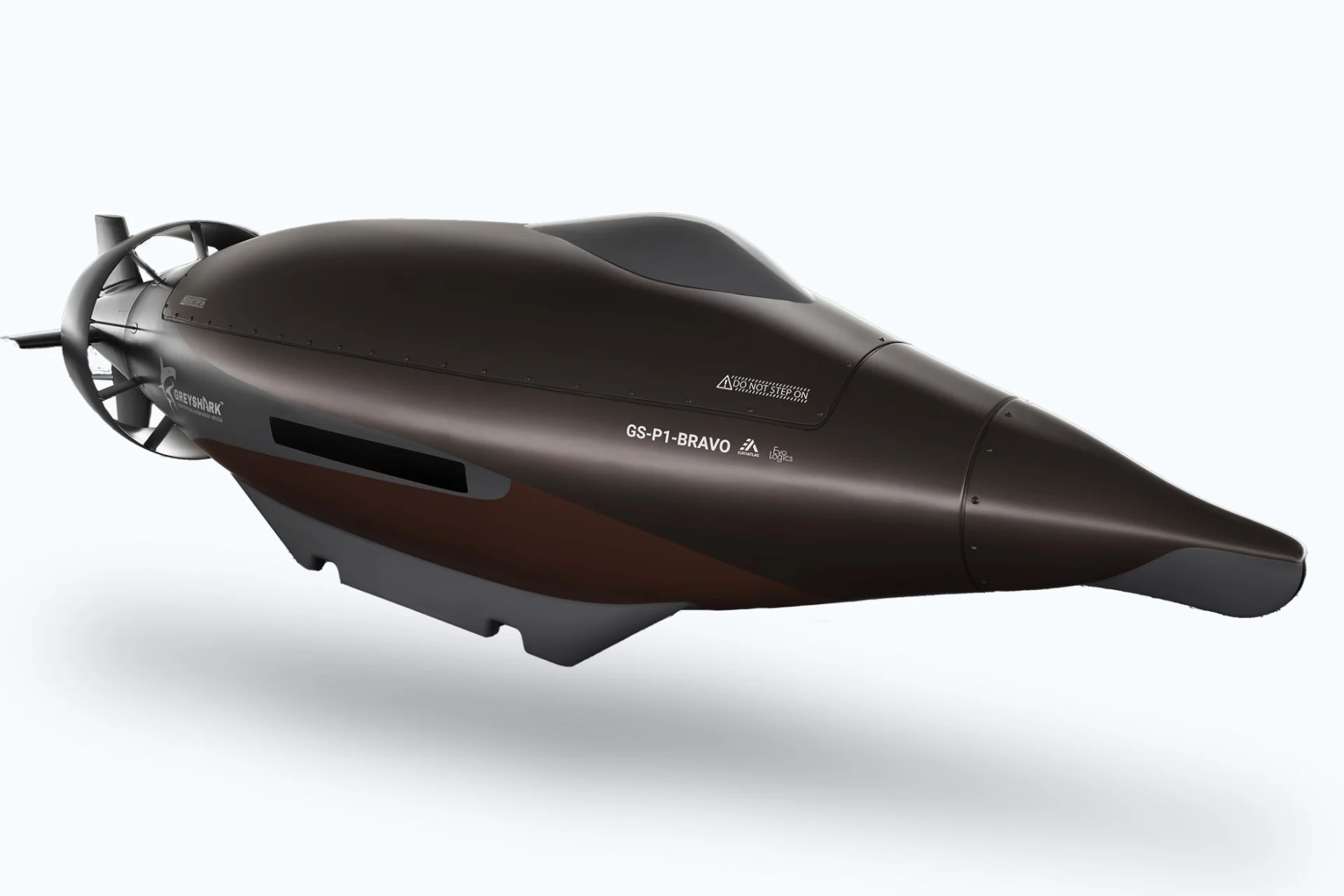

Autonomous Underwater Vehicles – GREYSHARK™

GREYSHARK™ is a state-of-the-art, fully autonomous underwater vehicle (AUV) designed for long-duration, versatile missions in complex maritime scenarios. With its extreme range, high speed, and superior sensor technology, GREYSHARK™ sets new standards in reconnaissance, surveillance, and protection of critical infrastructure.

With a range of over 1,000 nautical miles, an economical cruising speed of around 10 knots, and high-precision navigation, GREYSHARK™ is the long-range solution for pipeline protection, port security, and covert reconnaissance. The Autonomous Underwater Vehicle (AUV) is being developed in close collaboration between EUROATLAS GmbH, EvoLogics GmbH, and Fassmer—a trio that combines expertise to reliably monitor and defend critical underwater infrastructure.

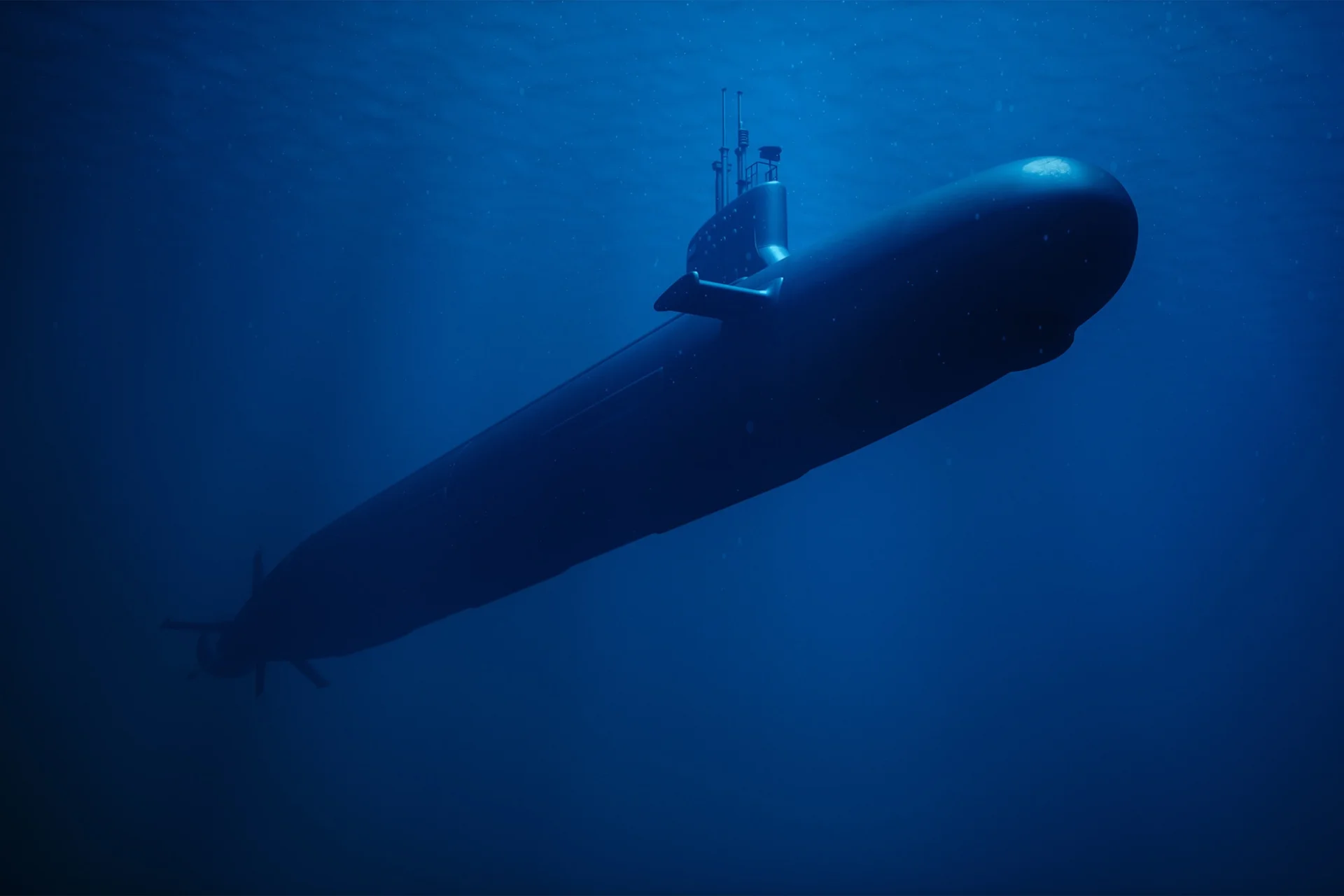

Composites in submarine construction

Every detail counts underwater. Carbon components offer decisive advantages:

- Corrosion-free even after years of use in salt water

- Non-magnetic – harder to detect, tactically superior

- Weight advantage – lower energy consumption, greater efficiency

- Less maintenance – higher operational readiness

This is how lightweight construction becomes the invisible strength of modern submarines – and Fassmer is part of this development.

High-tech above the waterline

The mast is more than just a support structure—it is the nerve center of modern ships. With carbon technology, we are taking it to a whole new level:

- Around 2.5 times lighter than steel

- Greater stability thanks to a low center of gravity

- High rigidity for radar systems and sensors

- Improved efficiency and range

One example: the 18-meter-high mast of the Fassmer OPV 90 – a symbol of how lightweight construction combines technology and operational strength.

Comfort meets lightweight construction

Shipping companies also rely on our composite solutions in civil shipping.

- One example: pool covers on cruise ships.

- Lightweight and robust – easy to handle yet highly resilient

- Corrosion-free – ideal for use in humid, salty environments

- Aesthetic and functional – precision-manufactured, durable in daily use

This demonstrates that whether on naval vessels or giant cruise ships, composites make all the difference.

Your benefits at a glance:

- Less weight – lower fuel consumption, greater range, higher payload

- Sustainable operation – noticeable CO₂ reduction in daily use

- Hardly any rust – composite is virtually corrosion-free and extremely durable

- Minimal servicing – less maintenance, greater availability

Got questions?

We’ve got answers.

Interested in our products and services? Our team is happy to assist you – and we look forward to hearing from you.

Your personal contact